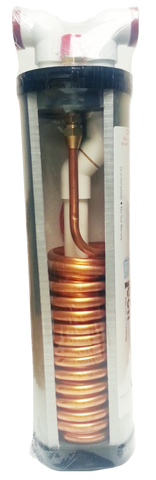

Systems IV ChillTech I, SIV CTI, Ice Machine Pre-Chill, 20% More Ice, Save Energy

Systems IV ChillTech I, SIV CTI, Ice Machine Pre-Chill, 20% More Ice, Save Energy is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

ChillTech I

PRE-CHILL TECHNOLOGY

- Increases ice production by up to 20%

- Lowers kWh consumption by up to 20%

- Stand alone product

- No replacement cartridges, one time purchase

- No electricity required

- Easily connects to cold water feed line

- Helps equipment operate at full capacity

The Marketplace is full of poor performing commercial ice machines. Most buyers purchase what they need at the time, and nothing more. Most businesses grow, and of course, the ice machine does not grow with them. Purchasing ice is expensive to say the least.

Performance on all ice machines is measured by ambient air temperature and incoming water temperature. Years ago a restaurant owner told us he loved his ice machine except that it didn’t make enough ice in the summer and made too much ice in the winter. We heard this over and over.

Temperature Reduction

We have found ChillTech not only reduces freeze times but also increased harvest weight which in turn reduces the amount of water purged at the cycles end. This means a highly reduced KWH consumption per 100 pounds of ice and a reduction in gallons of water used per pounds of ice harvested.

The exclusive ChillTech system will significantly reduce water temperature to incoming ice makers. This will reduce ice maker cycle times while increasing the ice making capacity of the ice maker by up to 30 percent.

Less kWh cost to the consumer results in a lower electric bill... This results in the ChillTech’s ability to pay for itself in less than

Systems IV® has developed ChillTech to be a very simple add on to existing or new ice machines. Designed to sit on the floor or attached via a simple mounting bracket that can be attached to the wall or the side of the bin for additional support.

a year and in many cases in 6 months or less.

ChillTech catches that wonderful free energy and transfers the cold left over water to the incoming warmer water in it’s system to bring the temperature down by up to 30%. The result is an ice maker that makes much more ice in the days and months and even years to come on FREE energy.

The ChillTech attaches to the existing drain line, and is very fast to install. MAINTENANCE FREE.

We developed the ChillTech to be simple...

Installation requires nothing more than taking the existing drain tubing from the ice maker itself and installing it to the inlet line and then installing the continuation drain line to the drain. The inlet potable water line to the ice maker needs to be routed to the marked flare fitting and the continuation to the ice maker from the flare fittings. It would be advisable, although not necessary to wrap the continuing water line to the ice maker with insulation. This would maintain the cold temperatures the ChillTech brings to the ice maker. An ice maker installed with a Systems IV® ChillTech will reduce freeze times.

Cooler temperatures mean less heat. Heat is wear. So, the customer can expect to find lower temperatures surrounding the ice maker - the condenser if air-cooled will discharge a slightly cooler air since it has less

heat to remove due to lighter load or temperature of the water. All the components will last longer as they are now operating for a shorter period of time.

How long will it take for the customer to know the ChillTech is working?

Almost immediately... The moment the customer has the ChillTech installed; it is working. There is no BREAK-IN period.

The essence of simplicity is generally what works! Today, GREEN is the issue... This product is about as green as it gets!

|

Dimensions: |

|

|

Micron - µm: |

N/A |

|

Flow Rate: |

N/A |

|

Fitting Size: |

1/2"NPT (available in 1/2"QC if specified) |

|

Capacities: |

Up to 1200lb/day cuber Hoshizaki Cubers up to 600lbs/day 5 Year Warranty |

Key product features

Can be highlighted here.

Description

Description

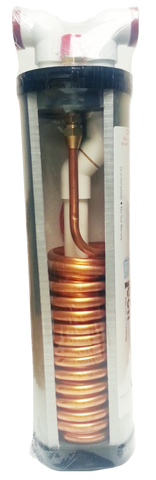

ChillTech I

PRE-CHILL TECHNOLOGY

- Increases ice production by up to 20%

- Lowers kWh consumption by up to 20%

- Stand alone product

- No replacement cartridges, one time purchase

- No electricity required

- Easily connects to cold water feed line

- Helps equipment operate at full capacity

The Marketplace is full of poor performing commercial ice machines. Most buyers purchase what they need at the time, and nothing more. Most businesses grow, and of course, the ice machine does not grow with them. Purchasing ice is expensive to say the least.

Performance on all ice machines is measured by ambient air temperature and incoming water temperature. Years ago a restaurant owner told us he loved his ice machine except that it didn’t make enough ice in the summer and made too much ice in the winter. We heard this over and over.

Temperature Reduction

We have found ChillTech not only reduces freeze times but also increased harvest weight which in turn reduces the amount of water purged at the cycles end. This means a highly reduced KWH consumption per 100 pounds of ice and a reduction in gallons of water used per pounds of ice harvested.

The exclusive ChillTech system will significantly reduce water temperature to incoming ice makers. This will reduce ice maker cycle times while increasing the ice making capacity of the ice maker by up to 30 percent.

Less kWh cost to the consumer results in a lower electric bill... This results in the ChillTech’s ability to pay for itself in less than

Systems IV® has developed ChillTech to be a very simple add on to existing or new ice machines. Designed to sit on the floor or attached via a simple mounting bracket that can be attached to the wall or the side of the bin for additional support.

a year and in many cases in 6 months or less.

ChillTech catches that wonderful free energy and transfers the cold left over water to the incoming warmer water in it’s system to bring the temperature down by up to 30%. The result is an ice maker that makes much more ice in the days and months and even years to come on FREE energy.

The ChillTech attaches to the existing drain line, and is very fast to install. MAINTENANCE FREE.

We developed the ChillTech to be simple...

Installation requires nothing more than taking the existing drain tubing from the ice maker itself and installing it to the inlet line and then installing the continuation drain line to the drain. The inlet potable water line to the ice maker needs to be routed to the marked flare fitting and the continuation to the ice maker from the flare fittings. It would be advisable, although not necessary to wrap the continuing water line to the ice maker with insulation. This would maintain the cold temperatures the ChillTech brings to the ice maker. An ice maker installed with a Systems IV® ChillTech will reduce freeze times.

Cooler temperatures mean less heat. Heat is wear. So, the customer can expect to find lower temperatures surrounding the ice maker - the condenser if air-cooled will discharge a slightly cooler air since it has less

heat to remove due to lighter load or temperature of the water. All the components will last longer as they are now operating for a shorter period of time.

How long will it take for the customer to know the ChillTech is working?

Almost immediately... The moment the customer has the ChillTech installed; it is working. There is no BREAK-IN period.

The essence of simplicity is generally what works! Today, GREEN is the issue... This product is about as green as it gets!

|

Dimensions: |

|

|

Micron - µm: |

N/A |

|

Flow Rate: |

N/A |

|

Fitting Size: |

1/2"NPT (available in 1/2"QC if specified) |

|

Capacities: |

Up to 1200lb/day cuber Hoshizaki Cubers up to 600lbs/day 5 Year Warranty |

Reviews (0)

Reviews (0)

Highlight title

Text to highlight a key feature of your product

Highlight title

Text to highlight a key feature of your product